In This Topic

Reference

The reference, Xm, serves as a point of comparison in a study. Usually, a reference value is determined by averaging multiple measurements of the reference part that are taken with lab-calibrated measuring equipment.

Ideally, Xm is close to the center of the tolerance zone for the characteristic that you measure.

Mean

The mean of the measurements of a part is calculated by:

Notation

| Term | Description |

|---|---|

| Xi | the measurement of the ith part |

| n | the number of measurements |

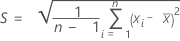

Standard deviation

The standard deviation of the measurements of a part is calculated by:

Notation

| Term | Description |

|---|---|

| the mean of n measurements |

| Xi | the measurement of the ith part |

| n | the number of measurements |

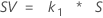

Study variation (SV)

The study variation is calculated by:

Notation

| Term | Description |

|---|---|

| k1 | Minitab uses the default value of 6 standard deviations from a standard normal distribution to represent 99.73% of your measurements. To change this value, see the Options sudialog box. For example, use the multiplier 5.15 to represent 99% of your measurements. |

| S | the standard deviation of the measurements |

Tolerance

The tolerance is specified for each component. You must enter either the tolerance or one of the specification limits.

Tolerance = USL – LSL or USL – 0 when the LSL is replaced by the natural zero.

Notation

| Term | Description |

|---|---|

| USL | the upper specification limit |

| LSL | the lower specification limit |

Resolution

The resolution is the specified gage resolution.

A guideline for the resolution is that it should not be greater than 5% of the tolerance. So, if you specify both the resolution and the tolerance, Minitab calculates whether the resolution is less than, greater than, or equal to 5% of the tolerance.

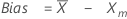

Bias

The gage bias is calculated by the difference between the mean of the n measurements and the reference value.

Notation

| Term | Description |

|---|---|

| the mean of n measurements |

| Xm | the reference measurement |

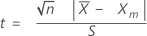

T

The t-statistic for testing the null hypothesis that bias = 0 versus the alternative hypothesis that bias ≠ 0.

t follows the t-distribution with γ degrees of freedom, where γ = n – 1.

Notation

| Term | Description |

|---|---|

| n | the number of measurements |

| the mean of n measurements |

| Xm | the reference measurement |

| S | the standard deviation of the measurements |

p-value

The p-value is associated with the t-statistic. It is the probability of obtaining a t-statistic as large or larger than the calculated one, assuming that the bias is zero. As the t-statistic increases, the p-value decreases. The smaller the p-value, the greater the evidence against the null hypothesis that the bias = 0.

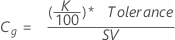

Cg

Capability indices are calculated only when the gage tolerance is specified. The capability of the gage is calculated by:

Notation

| Term | Description |

|---|---|

| K | the percent of the tolerance for calculating Cg specified in the Options subdialog box, default = 20 |

| SV | the study variation |

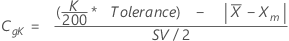

CgK

Capability indices are calculated only when the gage tolerance is specified. The capability of the gage, considering both the gage variation and the bias, is calculated by:

Notation

| Term | Description |

|---|---|

| K | the percent of the tolerance for calculating Cg specified in the Options subdialog box, default = 20 |

| the mean of n measurements |

| Xm | the reference measurement |

| SV | the study variation |

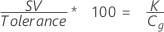

%Var (Repeatability)

% Var for repeatability compares the gage repeatability with the tolerance. % Var is calculated by dividing the study variation by the tolerance and multiplying by 100.

Notation

| Term | Description |

|---|---|

| K | the percent of the tolerance for calculating Cg specified in the Options subdialog box, default = 20 |

| SV | the study variation |

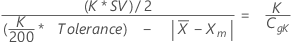

%Var (Repeatability and Bias)

% Var for repeatability and bias compares the gage repeatability and bias with the tolerance.

Notation

| Term | Description |

|---|---|

| K | the percent of the tolerance for calculating Cg specified in the Options subdialog box, default = 20 |

| the mean of n measurements |

| Xm | the reference measurement |

| SV | the study variation |