You can use a capability analysis to determine whether a process is capable of producing output that meets customer requirements, when the process is in statistical control.

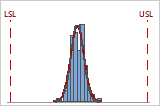

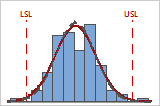

Usually, the capability of a process is determined by comparing the width of the process spread to the width of the specification spread, which defines the maximum amount of variation allowed based on customer requirements. When a process is capable, the process spread is smaller than the specification spread.

Capable

Not capable

Process capability

When your process is centered and well within the specification limits, it is more capable of consistently producing product that meets customer expectations.

A capability analysis can also indicate whether your process is centered and on target. In addition, it estimates the proportion of product that does not meet specifications.

- Probability plots and goodness-of-fit tests, to assess the distribution of the data.

- Control charts, to assess whether the process is in control.

- Is the variability of a process low enough to consistently provide parts that fall within the specification limits?

- Is the proportion of defectives consistently less than 5% during a month?

- Is a temperature curing process capable across multiple batches of the product?

- Does a process need to be shifted to operate within the specification limits?