In This Topic

The date and times are in UTC format in this listing.

Once imported, all the components of your subscription are stored in the Components area. For more information on the components library and setting up the components manually, go to Process, product, and station components.

Configuration types

Master data includes the company setup data. Components can be configured separately or together with measures; however, each measure type must have its own configuration setup.

- Products: Use to configure new or modify existing products.

- Processes: Use to configure new or modify existing processes.

- Stations: Use to configure new or modify existing stations.

- Descriptors: Use to configure new or modify existing descriptors. You can also provide related process information, and turn on control chart markers.

- Process Measures: Use to configure new or existing continuous process measures. You can also provide related process information.

- Output Measures: Use to configure new or existing output measures. You can also provide related process information.

- Defective Measures: Use to configure new or existing defective measures. You can also provide related process information.

- Grouped Defects: Use to configure new or

existing defects that are aggregated on a single control chart by severity

level. You can also provide related process information.

For example, suppose you have three defect types, such as Spots, Scratches, and Dents. Spots and Scratches have the same defect severity of Minor, and Dents have a severity of Major. In this case, two control charts are created. The first is for the Major defectsand plots only Dents. The second is for the Minor defects and plots an aggregate of Spots and Scratches.

- Grouped Defectives: Use to configure new or existing defective types that are aggregated on a single control chart. You can also provide related process information.

Note

For each measure, you must also configure the product and process, and optionally, the station.

Each configuration has required or optional variables. For more information on particular variable requirements, go to Variable specifications.

Import schedule

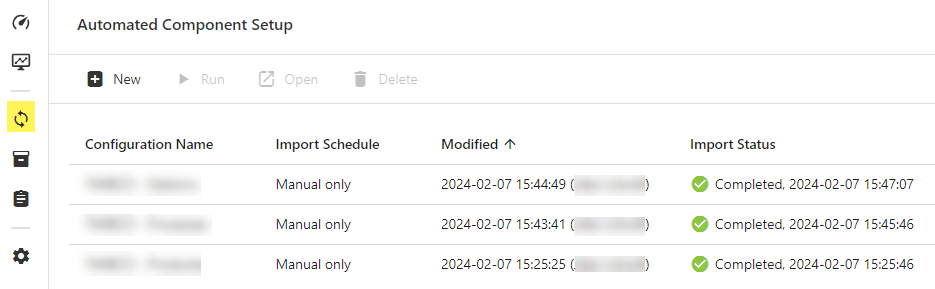

You can run a configuration import from the Automated Component Setup page. Simply select the configuration and then select the Run button.

- Daily

- Weekly

- Monthly

Note

If you do not want to set an automatic schedule, select Manual only.