In This Topic

Survival plot – Kaplan-Meier estimation method

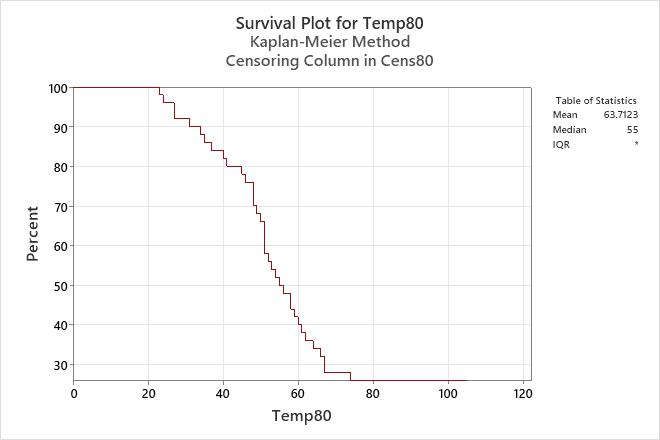

The survival plot depicts the probability that the item will survive until a particular time. Therefore, the plot shows the reliability of the product over time. The Y-axis displays the probability of survival and the X-axis displays the reliability measurement (time, number of copies, miles driven).

For a nonparametric analysis, the survival plot is a step function with steps at the exact failure times. By default, the function is calculated using the Kaplan-Meier method.

Example output

Interpretation

For the engine windings running at 80° C, the probability of surviving until 55 hours is 0.5. In other words, there is a 50% chance that the winding will survive until 55 hours.

Cumulative failure plot – Kaplan-Meier estimation method

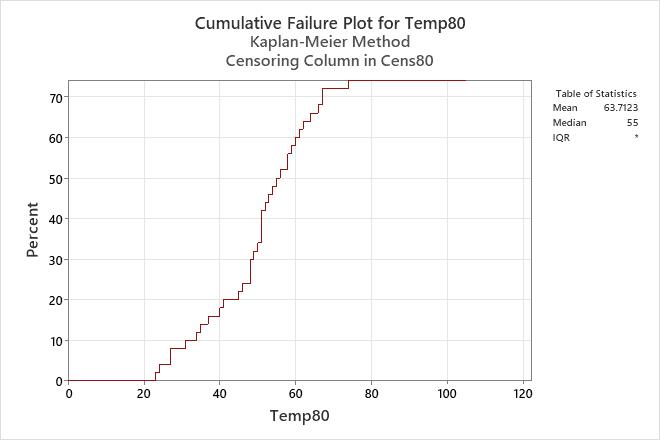

The cumulative failure plot depicts the probability that the item will fail after a particular time. Therefore, the plot shows the failure probability of the product over time. The Y-axis displays the probability of failure and the X-axis displays the reliability measurement (time, number of copies, miles driven).

For a nonparametric analysis, the cumulative failure plot is a step function with steps at the exact failure times. By default, the function is calculated using the Kaplan-Meier method.

Example output

Interpretation

For the engine windings running at 80° C, the probability of failing by 55 hours is 0.5. In other words, a 50% chance exists that the winding will fail at or before 55 hours.

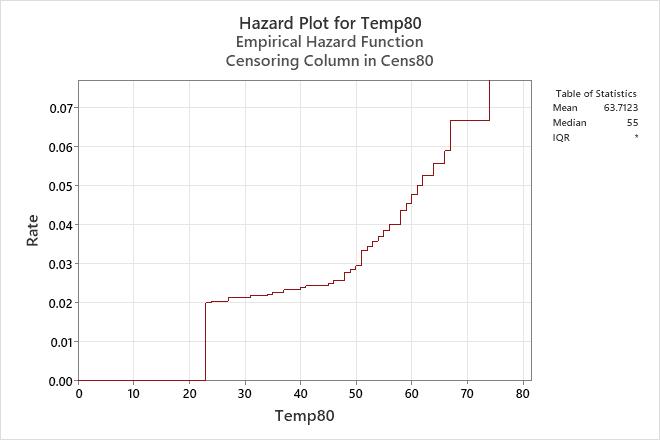

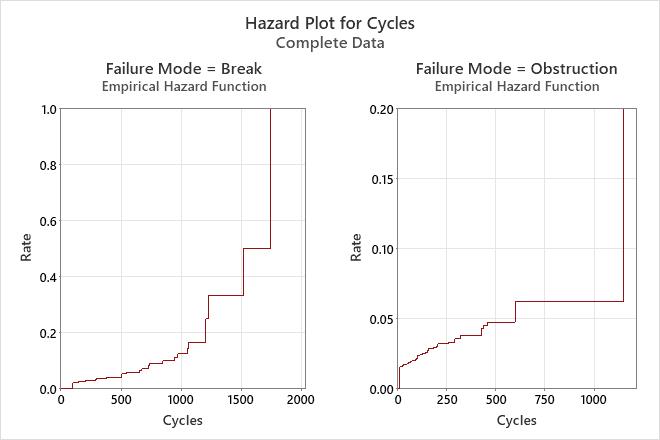

Hazard plot – Kaplan-Meier estimation method

The hazard function provides a measure of the likelihood of failure as a function of how long a unit has survived. The empirical hazard function always results in an increasing function. Therefore, the likelihood of failure is assumed to increase as a function of age.

For a nonparametric analysis, the hazard plot is a step function with steps at the exact failure times.

Example output

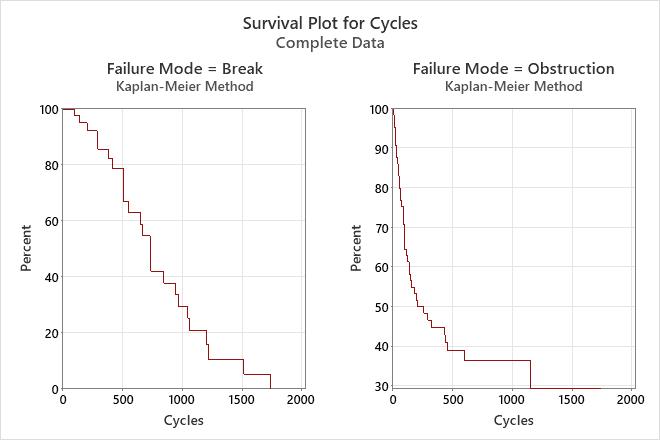

Multiple failure mode graphs – Kaplan-Meier estimation method

For the multiple failure data, Minitab displays graphs for each failure mode.

Interpret each graph as if only one failure mode were present.

Use the survival plot to assess the probability that the item will survive until a particular time. The survival plot shows the reliability of the product over time.

Use the hazard function to view the likelihood of failure as a function of how long a unit has survived (the instantaneous failure rate at a particular time, t). The hazard plot shows the trend in the failure rate over time.

Example output

Interpretation

For the dishwasher data, 95% of the spray arms survived breaks for at least 141.90 cycles, and 95% of the spray arms survived obstructions for at least 10.02 cycles.

To have the greatest impact on improving the reliability of the dishwashers, the engineers should focus on improving the spray arm obstructions.

The hazard rates for breaks and obstructions seem to increase slightly over time.