Variance components for the ANOVA method

The variance components in the table depend on whether the p-value for the Part*Operator interaction is less than the significance level for the analysis. By default, the significance level is 0.05. To change the significance level, choose , then change the value in Alpha to remove interaction term.

- Test-Retest Error (Repeatability)

-

Repeatability = MSRepeatability

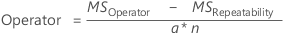

- Operator (Reproducibility)

- The calculation of the component includes the Part*Operator interaction when

the interaction is statistically significant. With the interaction, the

analysis uses the following formula:

- Part*Operator (Reproducibility)

-

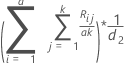

- Part (Product variation)

- The calculation of the component includes the Part*Operator interaction when the interaction is statistically significant. With the interaction, the analysis uses the following formula:

- Total

- When the analysis includes the interaction, the variance component for reproducibility includes the variance component for the operators and the variance component for the interaction. When the analysis does not include the interaction, the variance component for reproducibility is the variance component for the operators.

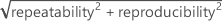

Variance components for the Xbar and R method

The variance is the square of the standard deviation.

- Test-Retest Error (Repeatability)

- Equipment variation, the standard deviation is calculated as:

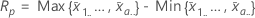

- Operator (Reproducibility)

-

Operator variation, the standard deviation is calculated as:

- Part (Product Variation)

-

The standard deviation is calculated as:

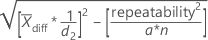

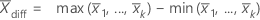

- Total Gage R&R

-

The standard deviation is calculated as:

- Total Variation

-

The standard deviation is calculated as: