A manufacturing engineer assesses the automated attribute measurement system that is used for accepting or rejecting bolts. The engineer selects 10 parts that have known reference values and runs each part through a go/no-gage 20 times. The engineer records the number of acceptances for each part.

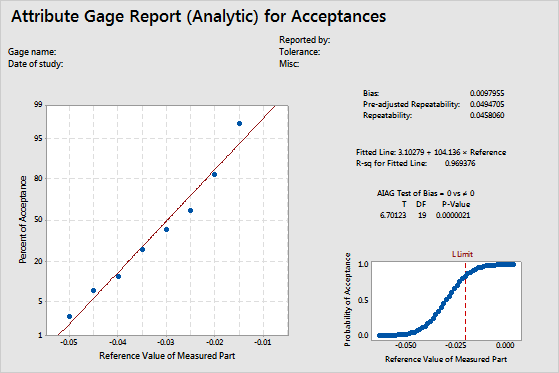

The engineer uses an attribute gage study to assess the bias and repeatability of the measurement system, and to determine whether to improve the measurement system.

The system has a lower tolerance of −0.020 and an upper tolerance of 0.020.

- Open the sample data, AutomotiveBolt.MWX.

- Choose .

- In Part numbers, enter Partnumber.

- In Reference values, enter Reference.

- Under Binary attributes in, select Summarized counts and enter Acceptances.

- In Number of trials, enter 20.

- In Attribute label, leave the default label of "Acceptance".

- Under Tolerance limit for calculation, select Lower limit and enter -0.020 .

- Click OK.

Interpret the results

The null hypothesis for the test for bias states that bias = 0. Because the p-value is less than the significance level of 0.05, the decision is to reject the null hypothesis and conclude that the attribute measurement system is likely to have bias.

The bias in the attribute gage system is 0.0097955.The engineer should repair or recalibrate the gage to reduce the bias.