Plotted points

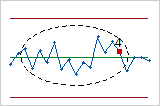

Each point on an NP chart represents the number of defective items or units for one subgroup.

Interpretation

If the process is in control, the points vary randomly around the center line, and the process exhibits only common-cause variation. Investigate points that fall outside the control limits or that exhibit nonrandom patterns for possible special-cause variation.

Center line

The center line on an NP chart represents the average number of defectives per subgroup. If the subgroups sizes are not equal, the center line is not straight on the NP chart.

Interpretation

Use the center line to observe how the process performs compared to the average. If the process is in control, then the points vary randomly around the center line.

CAUTION

Do not confuse the center line with the target value for your process. The target is your desired outcome. The center line is the actual outcome.

Control limits

CAUTION

Do not confuse control limits with specification limits. Specification limits represent customer requirements and indicate the amount of variation that you want to see in the process. Control limits represent the actual amount of variation that is in the sample data. A process can be in control, yet not be capable of meeting specifications.

Tests for special causes

The tests for special causes assess whether the plotted points are randomly distributed within the control limits.

Interpretation

Use the tests for special causes to determine which observations you may need to investigate and to identify specific patterns and trends in your data. Each of the tests for special causes detects a specific pattern or trend in your data, which reveals a different aspect of process instability. For example, Test 1 detects a single out-of-control point. Test 2 detects a possible shift in the process.

Four tests are available with this control chart.

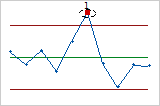

- Test 1: One point more than 3σ from center line

- Test 1 identifies subgroups that are unusual compared to other subgroups. Test 1 is universally recognized as necessary for detecting out-of-control situations. If small shifts in the process are of interest, you can use Test 2 to supplement Test 1 in order to create a control chart that has greater sensitivity.

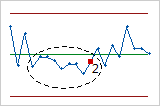

- Test 2: Nine points in a row on the same side of the center line

- Test 2 identifies shifts in the number of defectives for the process. If small shifts in the process are of interest, you can use Test 2 to supplement Test 1 in order to create a control chart that has greater sensitivity.

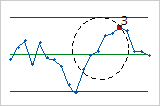

- Test 3: Six points in a row, all increasing or all decreasing

- Test 3 detects trends. This test looks for a long series of consecutive points that consistently increase in value or decrease in value.

- Test 4: Fourteen points in a row, alternating up and down

- Test 4 detects systematic variation. You want the pattern of variation in a process to be random, but a point that fails Test 4 might indicate that the pattern of variation is predictable.

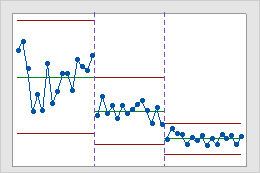

Stages

Use stages to create a historical control chart that shows how a process changes over specific periods of time. By default, Minitab recalculates the center line and control limits for each stage. For more information, go to Add stages to show how a process changed.

Interpretation

This historical control chart shows three stages of a process, which represent before, during, and after the implementation of a new procedure.