Use a Laney U' chart (U' is pronounced as U prime) to monitor the defect rate for your process and to adjust for overdispersion or underdispersion in your data. Overdispersion can cause a traditional U chart to show an increased number of points outside the control limits. Underdispersion can cause a traditional U chart to show too few points outside of the control limits. The Laney U' chart adjusts for these conditions. For more information, go to Overdispersion and underdispersion.

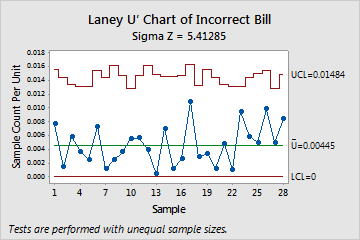

For example, the billing manager at a hospital wants to track the number of errors in the bills that the hospital sends to patients. Because the volume of bills is high, and the data exhibit overdispersion, the manager uses a Laney U' chart instead of a traditional U chart to monitor the defect rate. The chart shows that the average number of errors per bill is approximately 0.004, and that the process is in control.

Where to find this control chart

To create a Laney U' chart, choose .

When to use an alternate control chart

If you can determine only whether each item is defective or nondefective, use P Chart or Laney P' Chart to plot the proportion of defective items, or use NP Chart to plot the number of defective items.