In This Topic

Step 1: Check your data for problems

Your process should be stable and the process data should follow the nonnormal distribution that you selected for the analysis. The control charts and probability distribution plot allow you to evaluate whether these requirements are met.

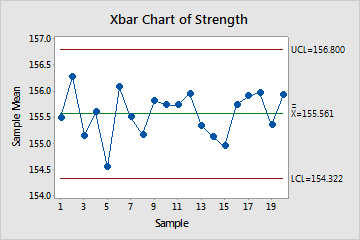

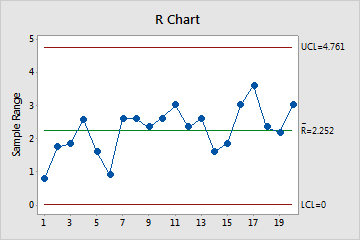

Determine whether your process is stable

Control charts help you monitor the stability of your process by identifying out-of-control points and patterns and trends in your data.

Red points indicate subgroups that fail at least one of the tests for special causes and are not in control. Out-of-control points indicate that the process may not be stable and that the results of a capability analysis may not be reliable. You should identify the cause of out-of-control points and eliminate special-cause variation before you analyze process capability.

In these charts, the points vary randomly around the center line and are within the control limits for both charts. No trends or patterns are present. The process is stable across the 20 subgroups.

Note

The type of control chart that Minitab displays depends on the size of the subgroups in your data:

- If the subgroup size is 1, Minitab displays an I chart with an MR chart

- If the subgroup size is greater than 1, Minitab displays an Xbar chart with either an R chart (when the subgroup is from 2 to 8) or an S chart (when the subgroup size is 9 or more).

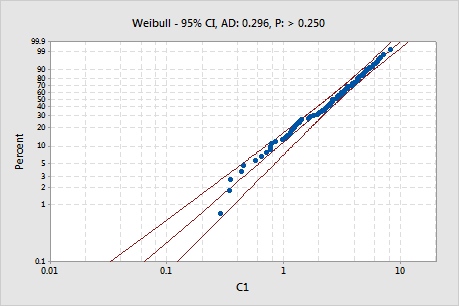

Assess the fit of the nonnormal distribution

Use the probability plot to assess the fit of the nonnormal distribution used for the analysis.

If the distribution is a good fit for the data, the points should form an approximately straight line. Departures from this straight line indicate that the fit is unacceptable. If the p-value is greater than 0.05, you can assume that the data follow the nonnormal distribution used in the analysis.

If the p-value is less than 0.05, your data do not follow the selected distribution and the capability analysis results may not be accurate. Use Individual Distribution Identification to determine which nonnormal distribution or data transformation is more effective for your data.

Key Result: P-value

In this plot, the points fall in an approximately straight line along the fitted (middle) line. The p-value is greater than 0.05, so there is not sufficient evidence that the data do not follow the selected nonnormal (Weibull) distribution. These data can be evaluated using nonnormal capability analysis with the Weibull distribution.

Step 2: Examine the observed performance of the process

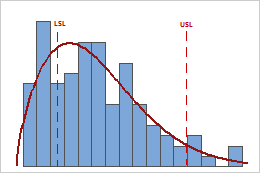

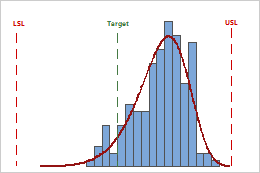

Use the capability histogram to visually examine the sample observations in relation to the process requirements.

Examine the process spread

Visually examine the data in the histogram in relation to the lower and upper specification limits. Ideally, the spread of the data is narrower than the specification spread, and all the data are inside the specification limits. Data that are outside the specification limits represent nonconforming items.

In this histogram, the process spread is larger than the specification spread, which suggests poor capability. Although much of the data are within the specification limits, there are many nonconforming items below the lower specification limit (LSL) and above the upper specification limit (USL).

Note

To determine the actual number of nonconforming items in your process, use the results for PPM. For more information, go to Capability statistics for Nonnormal Capability Sixpack and click "PPM Total for Expected Overall Performance".

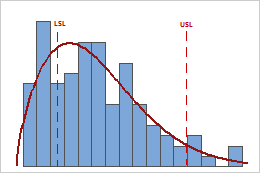

Assess the location of the process

Evaluate whether the process is centered between the specification limits or at the target value, if you have one. The peak of the distribution curve shows where most of the data is located.

In this histogram, although the sample observations fall inside of the specification limits, the peak of the distribution curve is not on the target. Most of the data exceed the target value and are located near the upper specification limit.

Step 3: Evaluate the capability of the process

Use Ppk to evaluate the overall capability of your process based on both the process location and the process spread. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher Ppk values indicate a more capable process. Lower Ppk values indicate that your process may need improvement.

Compare Ppk to a benchmark value that represents the minimum value that is acceptable for your process. Many industries use a benchmark value of 1.33. If Ppk is lower than your benchmark, consider ways to improve your process.

Key Result: Ppk

For these process data, Ppk = 0.44. Because Ppk is less than 1.33, the overall capability of the process does not meet customer requirements. You should take steps to improve the process.

Important

The Ppk index measures the capability of the process in relation only to the specification limit that is closest to the process mean. Therefore, it represents only one side of the process curve, and does not measure how the process performs on the other side of the process curve. If your process has nonconforming items that fall outside both specification limits, use additional capability measures to more fully evaluate process performance.