In This Topic

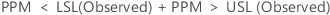

PPM < LSL for Observed Performance

The number of parts out of one million that have measurements that are less than the lower specification limit is calculated as follows:

Notation

| Term | Description |

|---|---|

| LSL | Lower specification limit |

| N | Total number of observations |

PPM > USL for Observed Performance

The number of parts out of one million that have measurements that are greater than the upper specification limit is calculated as follows:

Notation

| Term | Description |

|---|---|

| USL | Upper specification limit |

| N | Total number of observations |

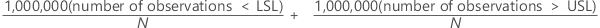

PPM Total for Observed Performance

The total number of parts out of a million that are outside the specification limits is calculated as follows:

Notation

| Term | Description |

|---|---|

| LSL | Lower specification limit |

| USL | Upper specification limit |

| N | Total number of observations |

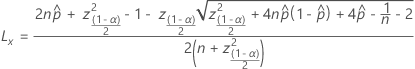

Confidence intervals for PPM and % out of specification

The calculation of the confidence interval is the same for PPM and percent except for a

step at the end to convert the result to the correct units. The following formulas are

for the two-sided 100(1 –  )% confidence intervals. To find

one-sided confidence intervals, replace

)% confidence intervals. To find

one-sided confidence intervals, replace  with (1 –

with (1 –  ).

).

To convert the result of the formula to PPM, multiply by 1,000,000.

To convert the result of the formula to percentage, multiply by 100.

If no observed units are outside of a specification limit, then the lower confidence bound is 0. If all the observed units are outside of a specification limit, then the upper confidence bound is 1.

Notation

| Term | Description |

|---|---|

| Lower confidence bound |

| Upper confidence bound |

| n | Total number of units |

| Empirical probability that a unit is out of specification: defectives / total. |

| (1 –  )/2 percentile from a standard normal distribution )/2 percentile from a standard normal distribution |

| 1 – the confidence level |

References

Newcombe, R. G. (1998). Two-sided confidence intervals for the single proportion: comparison of seven methods. Statistics in Medicine, 17(8), 857-872.

Tong, L. I., & Chen, J. P. (1998). Lower confidence limits of process capability indices for nonnormal process distributions. International Journal of Quality & Reliability Management, 15(8/9), 907-919.