A manufacturing engineer has implemented a variables sampling plan to verify the wall thickness of incoming 2-inch pipe. The lower specification for the pipe wall thickness is 0.09 inches. The engineer and the supplier agree that the AQL is 100 defectives per million and the RQL is 300 defectives per million. Based on these specifications, the engineer randomly selects and measures 104 pipes per lot of 2500 pipes. If the calculated Z-value is greater than the critical distance (3.55750), the engineer accepts the entire lot.

The shift supervisor is concerned that measuring 104 pipes will take too much time. The supervisor prefers to measure fewer pipes, such as 50 pipes. The engineer agrees to examine a few different sampling plans to determine the risks and benefits of each plan.

- Choose .

- From the drop-down list, select Compare User Defined Sampling Plans.

- In Units for quality levels, select Defectives per million.

- In Acceptable quality level (AQL), enter 100.

- In Rejectable quality level (RQL or LTPD), enter 300.

- In Sample sizes, enter 50 75 100 104.

- In Critical distances (k values), enter 3.55750.

- In Lower spec, enter 0.09.

- In Historical standard deviation, enter 0.025.

- In Lot size, enter 2500.

- Click OK.

Interpret the results

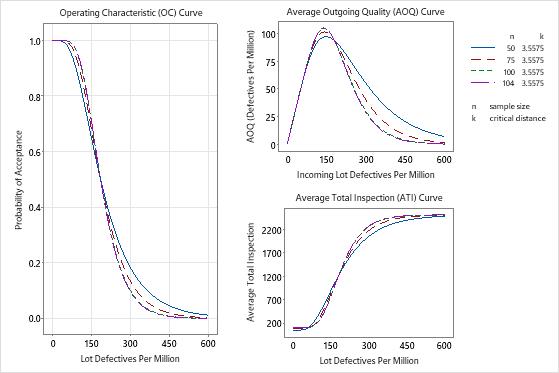

The engineer compares the graphs from the different sampling plans and realizes that the sample plans with sample sizes of 100 pipes and 104 pipes are very similar. The probability of acceptance at the AQL and the RQL changes by less than 0.5% (0.95 – 0.947). The AOQ change and the ATI change are also minimal.

The engineer also decides that a sample size of 50 pipes does not protect the quality level well enough. With a sample size of 50, the probability of accepting a lot at the RQL (300 PPM) is 18.7%. Also, the probability of rejecting a lot that should be accepted at the AQL (100 PPM) is 12.7%, which is too high for the producer.

The engineer is willing to consider the sampling plan of 75 pipes. The risks for the probabilities of acceptance seem reasonable, if the supplier agrees to reduce pipe thickness variability. The engineer decides to investigate other sample sizes that are between 75 and 100 pipes.

Method

| Lower Specification Limit (LSL) | 0.09 |

|---|---|

| Historical Standard Deviation | 0.025 |

| Lot Size | 2500 |

| Acceptable Quality Level (AQL) | 100 |

| Rejectable Quality Level (RQL or LTPD) | 300 |

Compare User Defined Plan(s)

| Sample Size(n) | Critical Distance(k) | Defectives Per Million | Probability Accepting | Probability Rejecting | AOQ | ATI |

|---|---|---|---|---|---|---|

| 50 | 3.5575 | 100 | 0.873 | 0.127 | 85.6 | 360.4 |

| 50 | 3.5575 | 300 | 0.187 | 0.813 | 54.9 | 2042.6 |

| 75 | 3.5575 | 100 | 0.919 | 0.081 | 89.1 | 271.3 |

| 75 | 3.5575 | 300 | 0.138 | 0.862 | 40.1 | 2165.8 |

| 100 | 3.5575 | 100 | 0.947 | 0.053 | 90.9 | 227.5 |

| 100 | 3.5575 | 300 | 0.104 | 0.896 | 30.0 | 2250.3 |

| 104 | 3.5575 | 100 | 0.950 | 0.050 | 91.1 | 223.2 |

| 104 | 3.5575 | 300 | 0.100 | 0.900 | 28.6 | 2261.3 |

Average Outgoing Quality Limit(s) (AOQL)

| Sample Size | Critical Distance(k) | AOQL | At Defectives Per Million |

|---|---|---|---|

| 50 | 3.5575 | 96.8 | 148.3 |

| 75 | 3.5575 | 101.0 | 141.9 |

| 100 | 3.5575 | 104.2 | 140.1 |

| 104 | 3.5575 | 104.6 | 140.0 |