A quality engineer at a canning company assesses whether the can-filling process is in control. Each hour, the engineer collects a subgroup of 10 cans. To minimize the within-subgroup (can-to-can) variation, the engineer collects the cans for a given subgroup in a short period of time.

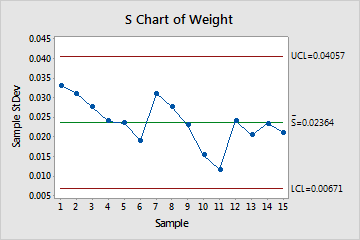

The quality engineer creates a S chart to monitor the variation in the weight of the cans.

- Open the sample data, CanWeight.MWX.

- Choose .

- From the drop-down list, select All observations for a chart are in one column, enter Weight.

- In Subgroup sizes, enter Subgroup ID.

- Click S Options.

- On the Tests tab, select 1 point > K standard deviations from center line (Test 1) and K points in a row on same side of center line (Test 2).If you are not sure which tests apply in your specific situation, use Tests 1 and 2.

- Click OK in each dialog box.

Interpret the results

None of the points are outside the control limits, and the points display a random pattern. Thus, the process variation is in control, and the engineer can examine the process center on the Xbar chart.