What are specification limits?

Specification limits are the values between which products or services should operate. These limits are usually set by customer requirements. For example, you print labels for a shipping process. If the labels are too big or too small, they will not feed into printers properly.

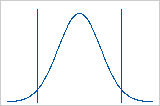

Examples of upper and lower specification limits

LSL = 2.5 USL = 2.687

The lower specification is 2.500 inches and the upper specification is 2.687 inches. Any labels that are smaller than 2.5 inches or larger than 2.687 inches are unacceptable.

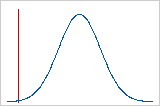

LSL = 80

Often, only one specification limit is used. For example, a chemical company requires an inert gas to be at least 80% pure. The quality analysts set a lower specification limit but do not set an upper specification limit because purer is better.

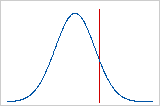

USL = 30

Conversely, consider a call center where calls must be answered within 30 seconds. In this case, only an upper specification is relevant because the quicker a call is answered, the better.

How are specification limits different from control limits?

Control limits are calculated from process data. They represent how your process actually performs. Specification limits are defined by your customer and represent the desired performance of your process.

Specification limits and control limits are used for different purposes. Control limits let you assess whether your process is stable. Specification limits allow you to assess how capable your process is of meeting customer requirements.

When should I define a specification limit as a boundary?

Instead of specification limits, a process may have boundaries. You should only define a specification limit as a boundary if it is not possible for data to exceed that specification limit. For example, a chemical company measures the percentage of purity of an inert gas and defines the upper specification of 100% as a boundary, because the gas cannot be more than 100% pure.

Choose . Check Boundary to indicate that a specification limit should be a boundary.

Note

Replacing one of your specification limits with a boundary in Minitab yields a one-sided capability analysis. If you select both specification limits as boundaries, all capability statistics will appear as asterisks (*) in the output.