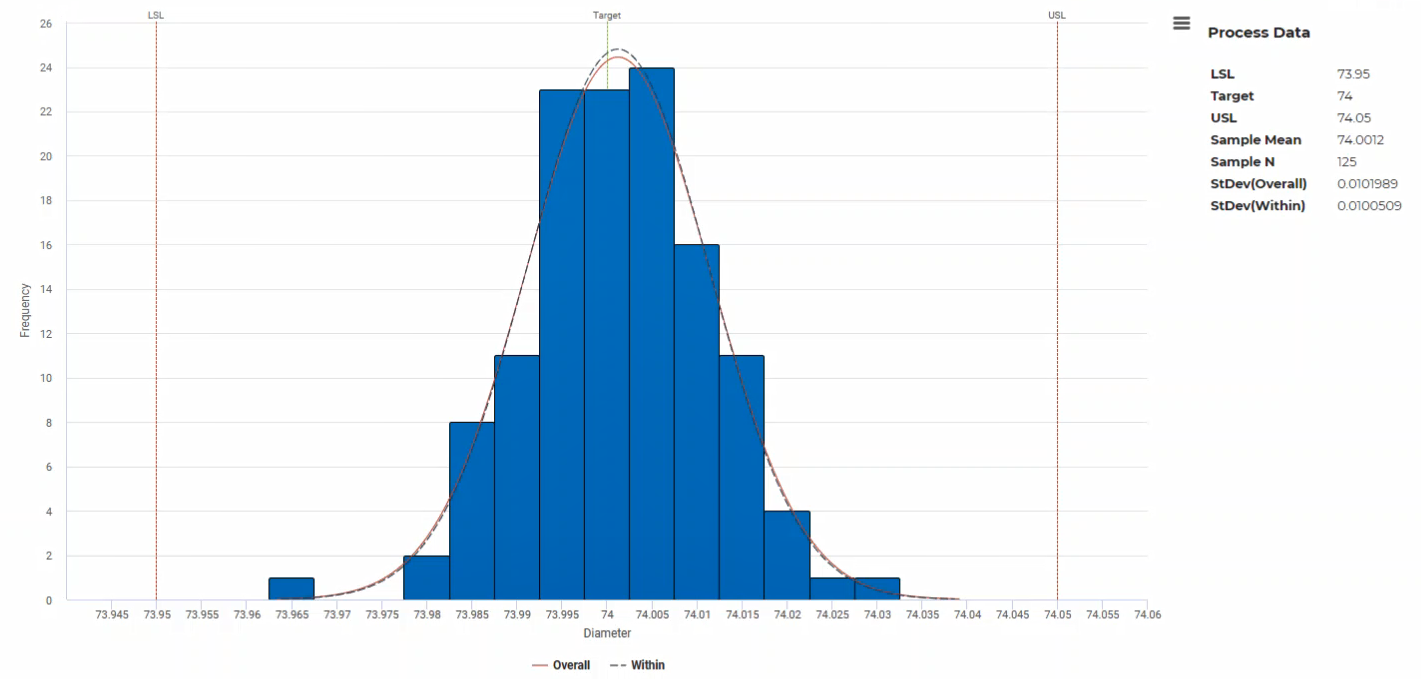

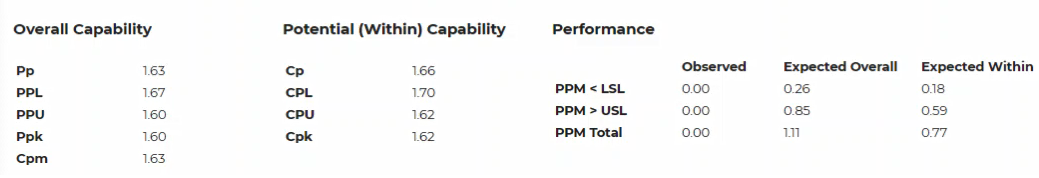

An engine manufacturer uses a forging process to make piston rings. The quality engineers want to assess the process capability. They collect 25 subgroups of five piston rings and measure the diameters. The specification limits for piston ring diameter are 74.0 mm ± 0.05 mm.

The engineers perform normal capability analysis to evaluate the diameters of the piston rings in relation to the specification limits.

-

Open the Prep tool

and import the data into a new table.

This example uses the data set in the Minitab Data Set Library, Piston ring data.

and import the data into a new table.

This example uses the data set in the Minitab Data Set Library, Piston ring data.Note

You cannot import a Minitab worksheet (MTW) into Minitab Connect. To import the data, save it as a CSV, XLSX, or copy and paste it. For more information on how to import data, go to Common tasks using the Base tool and select Import data to a new table from an Excel file.

-

Open the SPC tool

.

.

- In the first dropdown box, select Current Config.

- In Statistic, select Normal Capability Analysis.

- In Variable, select Diameter.

- In Subgroup sizes, select By value.

- In Subgroup size value, enter 5.

- In Lower spec, enter 73.95.

- In Upper spec, enter 74.05.

- Select Options, and then select Capability statistics options.

- In Target, enter 74.

-

Select Run

.

.

Interpret the results

All the measurements are within the specification limits. The process is on target and the measurements are approximately centered between the specification limits. The capability indices Cpk, Ppk, and Cpm are all greater than 1.33, which is a generally accepted minimum value for a capable process. Therefore, the engineers conclude that the forging process meets the requirements for the diameters of the piston rings.