Capability indices are ratios of the process spread and specification spread. They are unitless values so that you can use them to compare the capability of different processes. Some capability indices consider the process mean or target. Many practitioners consider 1.33 to be a minimum acceptable value for capability indices; and most practitioners believe a value less than 1 is not acceptable.

A company manufactures stainless steel bowls that are 12 cm in diameter. The customer requirements are that the bowls can be no smaller than 11 cm and no larger than 13 cm.

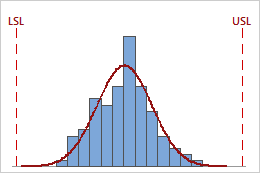

Specification spread is slightly greater than process spread, Cp=1.33

The mean is 11.95 cm and the overall standard deviation of the process is 0.25 cm. This process spread is represented by the data and the specification spread is between the 2 specification lines. This process is barely capable of consistently meeting the requirements. If the process were to shift, the process would not be acceptable.

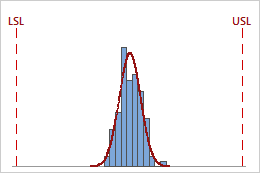

Specification spread is much greater than process spread, Cp=3.61

This process has been improved and the mean remains at 11.95 cm but the overall standard deviation of the process has reduced to 0.10 cm. The process spread is well contained inside the specification spread so this process is very capable of consistently meeting the requirements.