In This Topic

Pp

- The specification spread (USL – LSL)

- The spread of the process (the 6-σ variation) based on the overall standard deviation

You must provide both a lower specification limit (LSL) and an upper specification limit (USL) to calculate the Pp index.

Interpretation

Use Pp to evaluate the overall capability of your process based on the process spread. Overall capability indicates the actual performance of your process that your customer experiences over time.

Because Pp does not consider the location of the process, it indicates the overall capability that your process could achieve if it were centered. Generally, higher Pp values indicate a more capable process. Lower Pp values indicate that your process may need improvement.

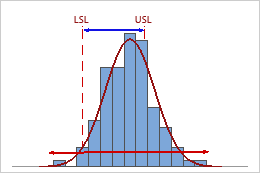

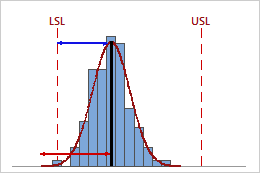

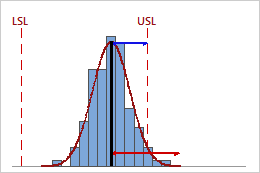

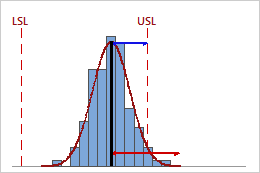

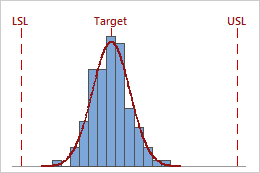

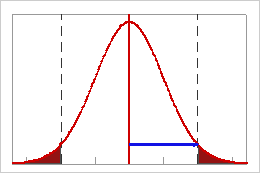

Low Pp

In this example, the specification spread is less than the overall process spread. Therefore, Pp is low (0.40), and the overall capability of the process is poor based on its variability.

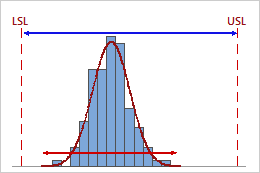

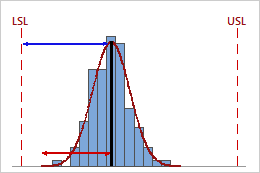

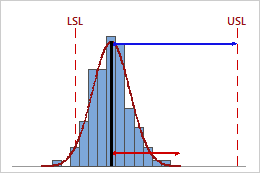

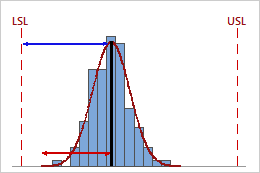

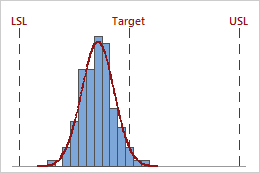

High Pp

In this example, the specification spread is considerably greater than the overall process spread. Therefore, Pp is high (1.80), and the overall capability of the process is good based on its variability.

-

Compare Pp to a benchmark value to assess the overall capability of your process. Many industries use a benchmark value of 1.33. If Pp is lower than your benchmark, consider how to improve your process by reducing its variation.

-

Compare Pp and Ppk. If Pp and Ppk are approximately equal, then the process is centered between the specification limits. If Pp and Ppk differ, then the process is not centered.

Caution

Pp = 2.27

Pp = 2.27

For a complete and accurate analysis, use graphs in combination with other capability indices (such as Ppk) to draw meaningful conclusions from your data.

PPL

- The distance from the process mean to the lower specification limit (LSL)

- The one-sided spread of the process (the 3-σ variation) based on the overall standard deviation

Interpretation

Use PPL to evaluate the overall capability of your process relative to its lower specification limit. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher PPL values indicate that the process is capable at the lower tail of its distribution. Lower PPL values indicate that your process may need improvement.

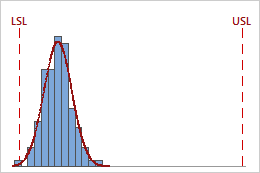

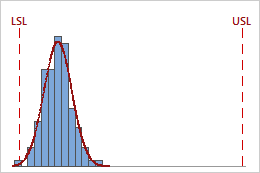

Low PPL

In this example, the distance from the process mean to the lower specification limit (LSL) is less than the one-sided process spread. Therefore, PPL is low (0.80), and the overall capability of the process is poor in relation to its lower specification limit.

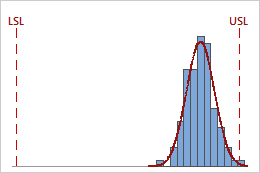

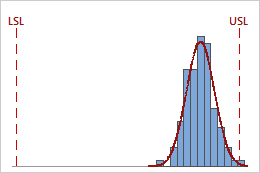

High PPL

In this example, the distance from the process mean to the lower specification limit (LSL) is greater than the one-sided process spread. Therefore, PPL is high (1.60), and the overall capability of the process is good in relation to its lower specification limit.

-

Compare PPL to a benchmark value to assess the overall capability of your process. Many industries use a benchmark value of 1.33. If PPL is lower than your benchmark, consider ways to improve your process, such as reducing its variation or shifting its location.

-

If you have both lower and upper specification limits, compare PPL and PPU. If PPL does not approximately equal PPU, the process is not centered.

PPL = 0.92, PPU = 4.37

When PPL < PPU, the process is more likely to produce defective units that violate the lower specification limit.

PPL = 4.37, PPU = 0.92

When PPU < PPL, the process is more likely to produce defective units that violate the upper specification limit.

PPU

- The distance from the process mean to the upper specification limit (USL)

- The one-sided spread of the process (the 3-σ variation) based on the overall standard deviation

Interpretation

Use PPU to evaluate the overall capability of your process relative to its upper specification limit. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher PPU values indicate that the process is capable at the upper tail of its distribution. Lower PPU values indicate that your process may need improvement.

Low PPU

In this example, the distance from the process mean to the upper specification limit (USL) is less than the one-sided process spread. Therefore, PPU is low (0.66), and the overall capability of the process is poor in relation to its upper specification limit.

High PPU

In this example, the distance from the process mean to the upper specification limit (USL) is considerably greater than the one-sided process spread. Therefore, PPU is high (2.76), and the overall capability of the process is good in relation to its upper specification limit.

-

Compare PPU to a benchmark value to assess the overall capability of your process. Many industries use a benchmark value of 1.33. If PPU is lower than your benchmark, consider ways to improve your process, such as reducing its variation or shifting its location.

-

If you have both lower and upper specification limits, compare PPL and PPU. If PPL does not approximately equal PPU, the process is not centered.

PPL = 0.92, PPU = 4.37

When PPL < PPU, the process is more likely to produce defective units that violate the lower specification limit.

PPL = 4.37, PPU = 0.92

When PPU < PPL, the process is more likely to produce defective units that violate the upper specification limit.

Ppk

- The distance from the process mean to the closest specification limit (USL or LSL)

- The one-sided spread of the process (the 3-σ variation) based on its overall variation

Interpretation

Use Ppk to evaluate the overall capability of your process based on both the process location and the process spread. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher Ppk values indicate a more capable process. Lower Ppk values indicate that your process may need improvement.

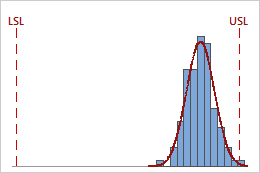

Low Ppk

In this example, the distance from the process mean to the nearest specification limit (USL) is less than the one-sided process spread. Therefore, Ppk is low (0.66), and the overall capability of the process is poor.

High Ppk

In this example, the distance from the process mean to the nearest specification limit (LSL) is greater than the one-sided process spread. Therefore, Ppk is high (1.68), and the overall capability of the process is good.

-

Compare Ppk to a benchmark value that represents the minimum value that is acceptable for your process. Many industries use a benchmark value of 1.33. If Ppk is lower than your benchmark, consider ways to improve your process.

-

Compare Pp and Ppk. If Pp and Ppk are approximately equal, then the process is centered between the specification limits. If Pp and Ppk differ, then the process is not centered.

-

Compare Ppk and Cpk. When a process is in statistical control, Ppk and Cpk are approximately equal. The difference between Ppk and Cpk represents the improvement in process capability that you could expect if shifts and drifts in the process were eliminated.

Caution

The Ppk index represents only one side of the process curve and does not measure how the process performs on the other side of the process curve.

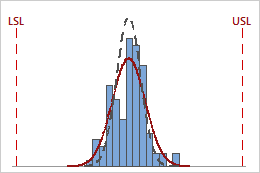

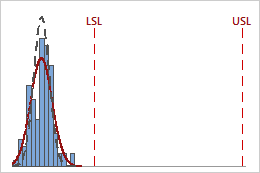

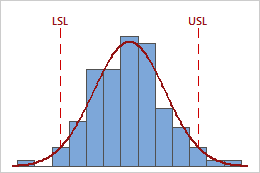

For example, the following graphs display two processes that have identical Ppk values. However, one process violates both specification limits, and the other process violates only the upper specification limit.

Ppk = min {PPL = 4.01, PPU = 0.64} = 0.64

Ppk = PPL = PPU = 0.64

If your process has nonconforming parts that fall on both sides of the specification limits, consider using other indices, such as Z.bench, to more fully assess process capability.

Cpm

Cpm is a measure of the overall capability of the process. Cpm compares the specification spread to the spread of your process data while taking into account how much the data deviate from the target value.

You must provide a target value for Minitab to calculate the Cpm.

Interpretation

Use Cpm to evaluate the overall capability of your process relative to both the specification spread and the target. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher Cpm values indicate that your process is more capable. Lower values indicate that your process may need improvement.

High Cpm

In this example, the data are on target and fall within the specification limits. Therefore, Cpm is high (1.60).

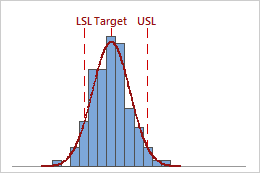

Low Cpm

In this example, the data fall inside of the specification limits, but the process is off target. Therefore, Cpm is low (1.03).

Low Cpm

In this example, the process is on target, but all of the data do not fall within the specification limits. Therefore, Cpm is low (0.48).

You can compare Cpm to other values to get more information about the capability of your process.

-

Compare Cpm with a benchmark value to assess the overall capability of your process. Many industries use a benchmark value of 1.33. If Cpm is lower than your benchmark, consider ways to improve your process, such as reducing its variation or shifting its location.

-

Compare Ppk and Cpm. If the process is centered on target, the Ppk and Cpm values are approximately equal.

Confidence interval (CI), Lower bound (LB), Upper bound (UB) for capability indices

The confidence interval is a range of likely values for a capability index. The confidence interval is defined by a lower bound and an upper bound. The bounds are calculated by determining a margin of error for the sample estimate. The lower confidence bound defines a value that the capability index is likely to be greater than. The upper confidence bound defines a value that the capability index is likely to be less than.

Note

To display confidence intervals, you must click Options and select Include confidence intervals when you perform the capability analysis. Minitab displays a confidence interval or a confidence bound for Cp, Pp, Cpk, Ppk, Cpm, and Z.bench.

Interpretation

Because samples of data are random, different samples collected from your process are unlikely to yield identical estimates of a capability index. To calculate the actual value of the capability index for your process, you would need to analyze data for all the items that the process produces, which is not feasible. Instead, you can use a confidence interval to determine a range of likely values for the capability index.

At a 95% confidence level, you can be 95% confident that the actual value of the capability index is contained within the confidence interval. That is, if you collect 100 random samples from your process, you can expect approximately 95 of the samples to produce intervals that contain the actual value of the capability index.

The confidence interval helps you to assess the practical significance of your sample estimate. When possible, compare the confidence bounds with a benchmark value that is based on process knowledge or industry standards.

For example, a company uses a minimum benchmark value of 1.33 for Ppk to define a capable process. Using capability analysis, they obtain a Ppk estimate of 1.46, which suggests that the process is capable. To further assess this estimate, they display a 95% lower confidence bound for Ppk. If the 95% lower confidence bound is greater than 1.33, they can be extremely confident that their process is capable, even when taking into account the variability from random sampling that affects the estimate.

Z.LSL for Overall Capability

Z.LSL (overall) is the number of standard deviations between the process mean and the lower specification limit (LSL). It is calculated based on the overall process performance, using the overall standard deviation.

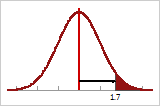

In this example, the overall standard deviation is represented by the tick marks on the horizontal scale. The distance between the process mean and the lower specification limit is 2 standard deviations, so the value of Z.LSL (overall) is 2.

Note

To display Z.bench measures, you must click Options and change the default output from capability statistics to benchmark Z's when you perform the capability analysis.

Interpretation

Use Z.LSL (overall) to evaluate the overall sigma capability of your process relative to the lower specification limit. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher Z.LSL values indicate that the process is capable at the lower tail of the distribution. Lower values indicate that your process may need improvement. When possible, compare Z.LSL (overall) with a benchmark value based on process knowledge or industry standards. If Z.LSL is less than your benchmark, consider ways to improve your process.

Z.USL for Overall Capability

Z.USL (overall) is the number of standard deviations between the process mean and the upper specification limit (USL). It is calculated based on the overall process performance, using the overall standard deviation.

In this example, the overall standard deviation is represented by the tick marks on the horizontal scale. The distance between the process mean and the upper specification limit is 2 standard deviations, so the value of Z.USL (overall) is 2.

Note

To display Z.bench measures, you must click Options and change the default output from capability statistics to benchmark Z's when you perform the capability analysis.

Interpretation

Use Z.USL (overall) to evaluate the overall sigma capability of your process relative to the upper specification limit. Overall capability indicates the actual performance of your process that your customer experiences over time.

Generally, higher Z.USL values indicate that the process is capable at the upper tail of the distribution. Lower values indicate that your process may need improvement. When possible, compare Z.USL (overall) with a benchmark value based on process knowledge or industry standards. If Z.USL is less than your benchmark, consider ways to improve your process.

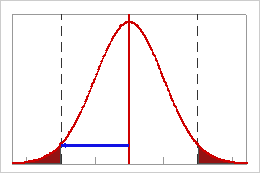

Z.Bench for Overall Capability

Z.bench (overall) is the percentile on a standard normal distribution that translates the estimated probability of defects in the process to an upper tail probability. It is calculated based on overall process performance, using the overall standard deviation.

The defects for the process fall on both sides of the specification limits. The overall standard deviations are shown by the tick marks.

If you put all the defects on the right tail of the distribution, and then measure the number of overall standard deviations from the center (vertical line) to the point that defines the total defects, you obtain the Z-bench (overall) value.

Note

To display Z.bench measures, you must click Options and change the default output from capability statistics to benchmark Z's when you perform the capability analysis.

Interpretation

Use Z.Bench (overall) to evaluate the overall sigma capability of your process.

Generally, higher Z.bench values indicate a more capable process. Lower Z.bench values indicate that your process may need improvement. When possible, compare Z.bench with a benchmark value based on process knowledge or industry standards. If Z.Bench is lower than your benchmark, consider ways to improve your process.

Compare Z.Bench (within) and Z.Bench (overall). When a process is in statistical control, Z.Bench (within) and Z.Bench (overall) are approximately equal. The difference between the two values represents the improvement in process capability that you could expect if the process were brought into control. Z.bench (overall) is sometimes referred to as Z.Bench Long-Term (LT).