Process Control for control charts

Add a control chart

To add a control chart, drag and place the control chart from the Assets pane ![]() onto the canvas. Minitab Solution Center adds a placeholder asset card that contains the default title, a representation

of the asset, and a drop down that contains the data associated with the dashboard.

Select the data that you want to use for the control chart. Then select Open to open the dialog for the control chart.

onto the canvas. Minitab Solution Center adds a placeholder asset card that contains the default title, a representation

of the asset, and a drop down that contains the data associated with the dashboard.

Select the data that you want to use for the control chart. Then select Open to open the dialog for the control chart.

Control charts

- Individuals Chart

- Use Individuals Chart to monitor the mean of your process when you have continuous data that are individual observations that are not in subgroups. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- I-MR Chart

- Use an I-MR Chart to monitor the mean and variation of your process when you have continuous data that are individual observations not in subgroups. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- Laney P' Chart

- Use a Laney P' Chart (P' is pronounced as P prime) to monitor the proportion of defective items that are produced by your process and to adjust for overdispersion or underdispersion in your data. Overdispersion can cause a traditional P chart to show an increased number of points outside the control limits. Underdispersion can cause a traditional P chart to show too few points outside of the control limits. The Laney P' chart adjusts for these conditions. For more information, go to Overdispersion and underdispersion.

- Xbar-R Chart

- Use an Xbar-R Chart to monitor the mean and variation of a process when you have continuous data and subgroup sizes of 8 or less. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- Xbar-S Chart

- Use an Xbar-S Chart to monitor the mean and variation of a process when you have continuous data and subgroup sizes of 9 or more. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- U Chart

- Use a U Chart to monitor the number of defects per unit, where each item can have multiple defects. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- P Chart

- Use a P Chart to monitor the proportion of defective items where each item can be classified into one of two categories, such as pass or fail. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- C Chart

- Use a C Chart to monitor the number of defects where each item can have multiple defects. You should use a C chart only when your subgroups are the same size. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.

- EWMA Chart

- Use an EWMA Chart to detect small shifts in the process mean, without influence by low and high values. The EWMA chart monitors exponentially weighted moving averages, which remove the influence of low and high values. The observations can be individual measurements or subgroup means. An advantage of EWMA charts is that they are not greatly influenced by low or high values.

Enter your data

The method to enter your data depends on the type of control chart. Select the option below that matches your data entry setup.

Variable

For an Individuals Chart, I-MR Chart, and C Chart, all the measurements for a variable must be in one column. In Variable, enter one column of measurement data.

| C1 |

|---|

| Weight |

| 785.92 |

| 830.36 |

| 798.43 |

| 812.56 |

| 799.63 |

| 822.72 |

| 786.64 |

| 803.66 |

| 811.29 |

| 826.74 |

All observations for a chart are in one column and Observations for a subgroup are in one row of columns

- All observations for a chart are in one column

-

If the measurement data are in one column, select this option, then enter a column of measurement data. In Subgroup sizes, if all subgroups are the same size, enter the subgroup size. Otherwise, enter a column of values that identifies which subgroup each measurement is from.

In this worksheet, Measurements contains the measurement data. Subgroup identifies which subgroup each measurement is from.C1-T C2 Subgroup Measurements One 10 One 13 One 10 Two 8 Two 8 Two 9 - Observations for a subgroup are in one row of columns

-

If each row in the worksheet contains the measurement data for one subgroup, select this option, then enter the columns that contain the measurement data.

In this example, Measurement_1, Measurement_2, and Measurement_3 contain the measurement data. The data for subgroup 1 are in row 1, the data for subgroup 2 are in row 2, and so on.C2 C3 C4 Measurement_1 Measurement_2 Measurement_3 10 13 10 8 8 9

Variable and Subgroup sizes

For a Laney P' Chart, U Chart, and P Chart, you must enter a variable column and specify the subgroup size. In Variable, enter the column that contains the process data.

- If all subgroups are the same size, enter the size (for example, 55).

- Enter a column that contains the size of each subgroup.

| C1 | C2 |

|---|---|

| Irregularities | Yards Sampled |

| 10 | 120 |

| 8 | 110 |

| 7 | 110 |

| 7 | 115 |

Weight of EWMA

In Weight of EWMA, enter the weight to use in the exponentially weighted moving average. The value must be between 0 and 1. If you change the default weight (0.2) and the number of standard deviations for the control limits, you can construct a chart with specific properties. Choose the weight based on how small of a shift you want to detect and how fast you want to detect that shift while maintaining an acceptable false alarm rate. You can choose combinations of these two parameters by using an ARL (average run length) table. See Lucas et al.1 for an extensive table.

Scale

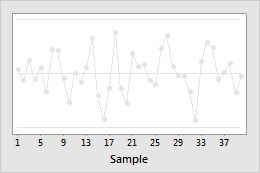

Specify a time scale for the x-axis.

- Index

-

Label the x-axis with the number of the subgroup.

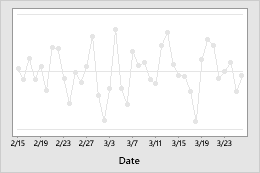

- Stamp

-

Label the x-axis with values from a column. In Stamp column, enter a column that contains date/time, numeric, or text values for the scale.

Parameters

- Mean

- Enter a single mean for the entire chart. The mean is used to calculate the center line on the individuals chart.

- Standard deviation

- Enter a single standard deviation for the entire chart. The standard deviation is used to calculate the control limits on both charts and the center line on the moving range chart.

- Proportion

- Enter a single proportion for the entire chart.

Estimate

The following options are on the Estimate tab of the Options sub-dialog.

Specify observations to estimate parameters

If some observations have erratic data because of special causes that you have corrected, you can omit these observations from the calculations to avoid incorrect parameter estimates.

- From the drop-down list, specify whether you want to list the

observations to omit, or the observations to include.

- To list the observations to omit, select Omit the following subgroups when estimating parameters.

- To list the observations to include, select Use the following subgroups when estimating parameters.

-

List the observations. Use a colon to indicate a range of observations. Leave a space between each observation or range of observations.

For example, to specify observations 2, 9, 44, 45, 46, and 47, enter 2 9 44:47.

Method for estimating standard deviation

- Average moving range

- The average moving range is the average value of the moving range of two or more consecutive points. Use this method when the subgroup size is 1.

- Median moving range

- The median moving range is the median value of the moving range of two or more consecutive points. Use this method when the data have extreme ranges that influence average of the moving ranges.

- Rbar

- Rbar is the average of the subgroup ranges. The Rbar method is a common estimate of the standard deviation and works best with subgroup sizes from 2 to 8.

- Sbar

- Sbar is the average of the subgroup standard deviations. The Sbar method provides a more precise estimate of the standard deviation than Rbar, especially with subgroup sizes greater than 8.

- Square root of MSSD

- The square root of MSSD is the square root of the mean of the squared differences between consecutive points. Use this method when you cannot reasonably assume that at least 2 consecutive points were collected under similar conditions.

- Pooled standard deviation

- The pooled standard deviation is the weighted average of subgroup variances, which gives larger subgroups more influence on the overall estimate. The pooled standard deviation method provides a more precise estimate of the standard deviation when the process is in control.

Select Use unbiasing constant to eliminate bias that can occur when you estimate certain process parameters. Often, the choice to use unbiasing constants depends on company policy or industry standards.

Length of moving range

Enter the number of observations that are used to calculate the moving

range. By default, a length of 2 is used because consecutive values have the

greatest chance of being alike. The length must be  100.

100.

If the data are cyclical, consider using a moving range of a different length. For example, if you collect quarterly data, consider using a moving range of length 4 to ensure that one observation from each season is included in the calculation.

Use Nelson estimate

On the Estimate tab of the I-MR Options subdialog, select Use Nelson estimate to correct for unusually large moving range values in the calculation of the control limits. The procedure is similar to the procedure proposed by Nelson. Connect eliminates any moving range values that are more than 3 standard deviations larger than the average moving range, then recalculates the average moving range and the control limits.

Limits

By default, Connect calculates the control limits using the actual subgroup sizes. When the subgroup sizes differ, the control limits are uneven, but you can force the control limits to be straight. Under When subgroup sizes are unequal, calculate control limits, select Assuming all subgroups have size, and enter a subgroup size.

CAUTION

When you specify a subgroup size, you change the calculations for the control limits, which can change the results of the tests for special causes. Use this option only if the differences between the subgroup sizes are small. Don't use this option when the difference between subgroup sizes is more than 25%. For example, if the largest subgroup has 10 observations and the smallest subgroup has 8 observations, then the difference is 20% ((10 - 8) / 10 = 0.2 = 20%).

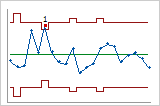

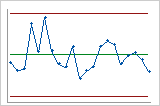

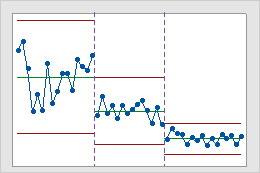

For example, the data for the following charts is the same, but the control limits for the second chart were calculated based on a fixed subgroup size.

Actual subgroup sizes

Fixed subgroup size

Tests

On the Options subdialog, Connect provides one to eight tests for special causes, depending on the control chart. By default, Connect uses only Test 1. Select additional tests based on company or industry standards. Use the tests to determine which observations to investigate, and to identify the specific patterns and trends in your data.

In the drop-down list, specify whether to perform some, all, or no tests for special causes. You can make each test more or less sensitive by changing the value of K.

- 1 point > K standard deviations from center line

- Test 1 identifies subgroups that are unusual compared to other subgroups. Test 1 is universally recognized as necessary for detecting out-of-control situations. If small shifts in the process are of interest, you can use Test 2 to supplement Test 1 in order to create a control chart that has greater sensitivity.

- K points in a row on same side of center line

- Test 2 identifies shifts in the process centering or variation. If small shifts in the process are of interest, you can use Test 2 to supplement Test 1 in order to create a control chart that has greater sensitivity.

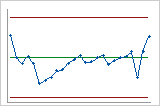

- K points in a row, all increasing or all decreasing

- Test 3 detects trends. This test looks for a long series of consecutive points that consistently increase in value or decrease in value.

- K points in a row, alternating up and down

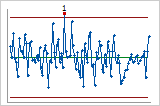

- Test 4 detects systematic variation. You want the pattern of variation in a process to be random, but a point that fails Test 4 might indicate that the pattern of variation is predictable.

- K out of K+1 points > 2 standard deviations from center line (same side)

- Test 5 detects small shifts in the process.

- K out of K+1 points > 1 standard deviation from center line (same side)

- Test 6 detects small shifts in the process.

- K points in a row within 1 standard deviation of center line (either side)

- Test 7 detects a pattern of variation that is sometimes mistaken as evidence of good control. This test detects control limits that are too wide. Control limits that are too wide are often caused by stratified data, which occur when a systematic source of variation is present within each subgroup.

- K points in a row > 1 standard deviation from center line (either side)

- Test 8 detects a mixture pattern. In a mixture pattern, the points tend to fall away from the center line and instead fall near the control limits.

Stages

This historical control chart shows three stages of a process, which represent before, during, and after the implementation of a new procedure.

In the example below, the values in the Stage column change from 1 to 2 to indicate the beginning of stage 2. The values change from 2 to 3 to indicate the beginning of stage 3.

| C1 | C2 |

|---|---|

| Measurements | Stage |

| ... | ... |

| 9 | 1 |

| 10 | 1 |

| 8 | 2 |

| 11 | 2 |

| ... | ... |

| 7 | 2 |

| 8 | 2 |

| 5 | 3 |

| 7 | 3 |

| ... | ... |

Display

To see only the most recent observations instead of all observations, enter the number of observations to include in the chart. Connect still uses all the data to calculate the control limits and the center line.

Note

By default, Connect displays the last 25 observations. This is different than Minitab Statistical Software, which displays all observations by default. This could result in different results if you don't change the settings making charts with the same data between the two applications.

- All

-

Connect displays all observations.

- Last

-

This chart displays only the most recent number of observations that you enter.

Add Reference Line

- Name

- The name you specify appears on the right side of the chart beside the reference line.

- Value

- Enter a value on the y-axis for the reference line.

- Line Color

- Specify a color for the reference line.

After you add a reference line, you can use the Graph Options tab to change the value, color, and name of the line, change the alert status, or delete the line.