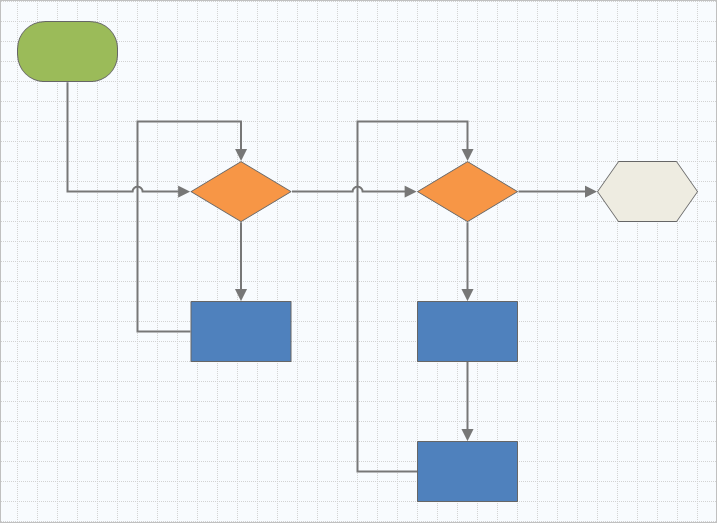

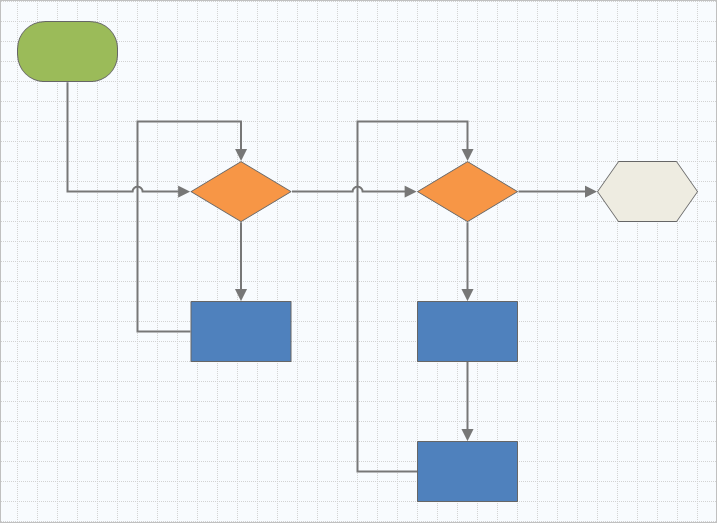

Use a process map to illustrate the sequential flow and the

relationship of steps in a process or procedure.

Process maps help you to understand and to communicate the activities, or

steps, in a process. Process maps also help you to see the relationship between

inputs and outputs in a process, identify key decision points, and uncover

rework loops.

A process map answers the following questions.

- Which areas of the process show the greatest opportunity for improvement?

- For a specific project, where does the process start and end?

- What are the inputs and outputs of each step in the process?

- Which steps are the bottlenecks and sources of defects?

- Which steps have a direct impact on customer requirements?

- Can you simplify, combine, or eliminate steps in the process?

How-to

- As a team, determine where the process starts and where it ends, then walk through each step of the process.

- Identify the data associated

with each step of the process. Consider the following items.

- Activities: Names of the steps in the process map.

- Inputs: X variables that can influence the output of interest, either directly or indirectly.

- Outputs: Y variables that depend on X variables.

- Process data: Information that further defines the characteristics of a process, such as the yield or DPMO at each step.

- Lean data: Information that is used to identify and eliminate waste, such as resource utilization or cycle time at each step.

- Record the collected information in a process map.

For more information, go to Add a map.