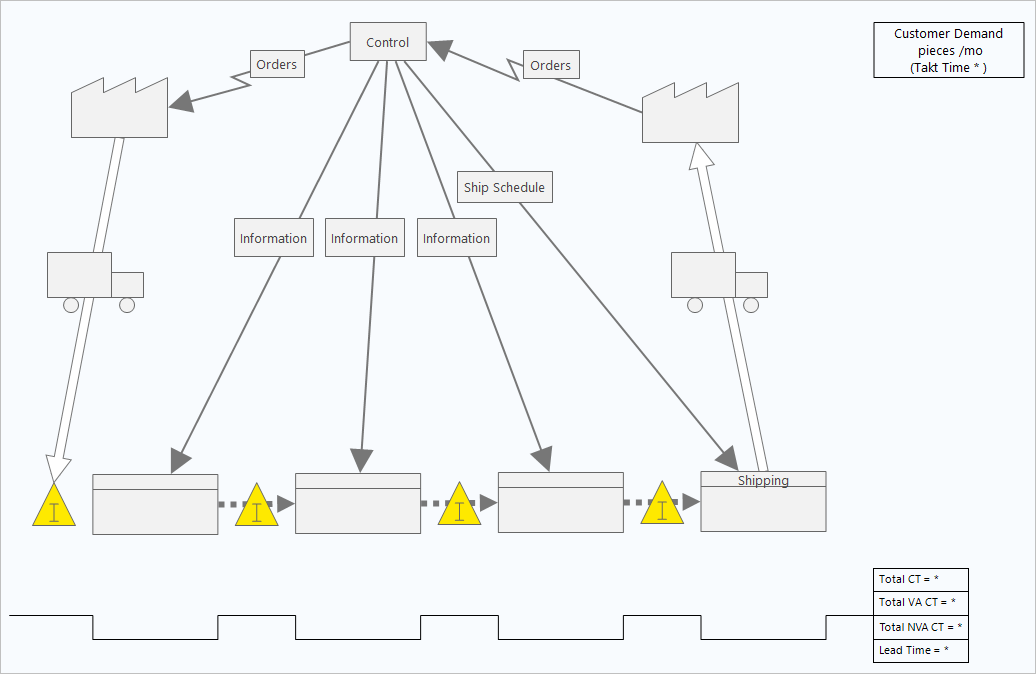

Use a value stream map to illustrate the flow of materials and

information as a product or service moves through the value stream.

A value stream map includes all the required activities that generate a

product or service.

You can create value stream maps that represent your current process or the process that you hope to have in the future.

Current state map

A current state value stream map identifies waste and helps you to envision an improved future state.

The current state map answers the following questions.

- What does the actual process look like at the beginning of the project?

- Where does the process start and end?

- How does value flow through the process?

- What steps in the process add value and what steps do not add value?

- What is the relationship between information flow and material flow?

- What is the average cycle time through the process?

- What level of inventory is held within the process and where is it located?

- What are the sources of the waste in the value stream?

- What areas of the process need the most improvement?

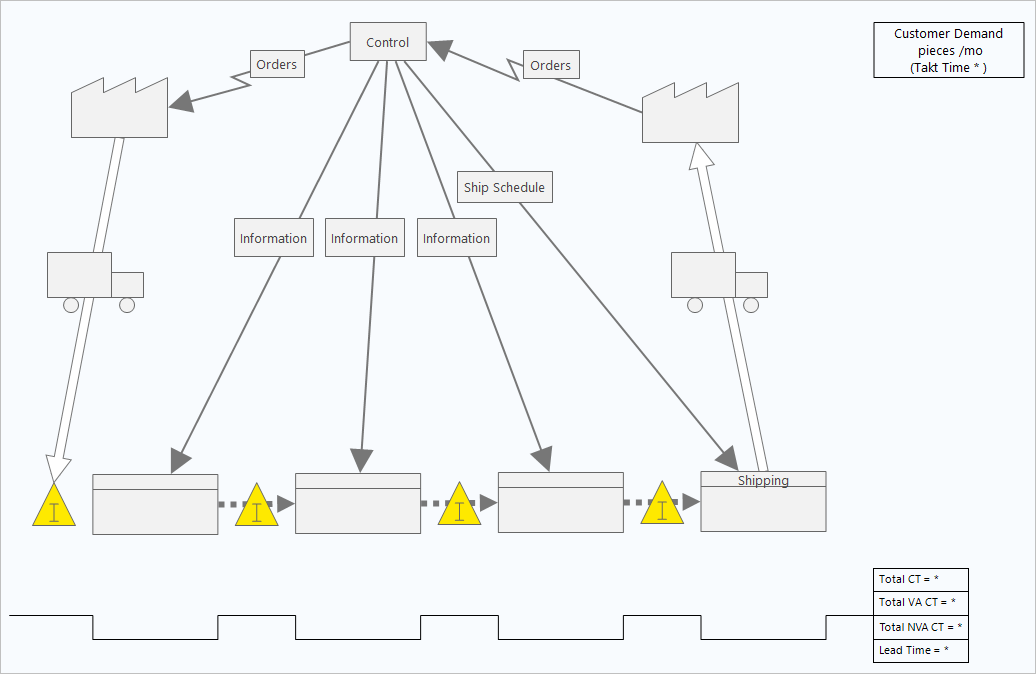

Future state map

Create a future state map from the current state map. Because you can always improve your process, you can always create a future state map. Continuous improvement is a major focus of the value stream map.

The future state map answers the following questions.

- Where will you need supermarket pull systems to control upstream processes?

- Where can you use continuous flow processing?

- When will you schedule production?

- How will you level the production mix?

- How can you simplify or eliminate any steps in the process?

- What does the actual process look like at the end of the project?

How-to

- Assign a value stream map manager to lead the mapping effort and draw the entire value stream map even if a team is involved in the project. This ensures that the manager understands the material and information flows.

- Identify the internal and external customers of the process and their customer requirements. It is important to have a clear understanding of what value means to the customer.

- Walk through the process to

ensure that the flow of materials and information is accurate.

- Determine where the process starts and where it ends. When you walk the process to document the current state, note the wastes that help you create a future state map.

- Begin at the end of the process and work upstream to gather details about each step in the process, such as cycle time, inventory, machine uptime, distance to adjacent steps, defect information, changeover frequency, and changeover time.

- Capture the process as it operates at this moment, not how it was originally designed to operate or how it should operate.

- Focus on one small step at a time. You can use a stopwatch to obtain cycle times.

- Identify critical paths and bottlenecks.

- With the process documented, you can divide the value stream into logical subsections based on key internal outputs, skills, or operational locations.

- Create the future state map.

- Implement your plan to achieve the future state. A new current state emerges, along with the need to draw a new future state map in a cycle of continuous improvement.

For more information, go to Add a map.